In this era of exascale computing, simulations play a pivotal role in addressing numerous scientific and engineering challenges. Whether it’s forecasting the weather, modeling chemical processes, analyzing seismic data, or optimizing cooling systems for next-generation silicon chips in large data centers, simulations offer essential insights for visualizing designs. Particularly within the automotive industry, computer-aided engineering (CAE) simulations prior to the production process can provide valuable information regarding vehicle crashworthiness and durability. The data enables faster insights into product behavior, providing crucial information, such as noise, vibration, and harshness, regarding their performance under real-world conditions. However, having the appropriate infrastructure to streamline this process is crucial.

For those unfamiliar, CAE simulation deals with three-dimensional objects, but its function surpasses visual representation. It not only aims to mimic the ‘real thing’ but also requires reliability in predicting various engineering variables. Consider a wind tunnel or the airflow around a race car, CAE plays a crucial role in assessing the forces acting on the car and the drivability which aid in the development of its design and strategies. Therefore, CAE extends beyond a vehicle’s external appearance, it entails an engineering analysis and simulation of the entire product. In the case of a crash test, a CAD design of components or a whole vehicle is analyzed and enhanced through geometry and environmental assumptions to predict results. A good example is the use of computational fluid dynamics (CFD) and finite element analysis (FEA), which are typically calculated through a time-consuming process of numerically solving mathematics and physical problems using computational software. The computation of these algorithms is usually computationally and memory-intensive, leading to longer development cycles, which can deter companies aiming for rapid product design and development where overall design significantly impacts efficient operation. With this time gap between design creation and design verification, one might question if there is a way to streamline this process and reduce hours of calculation and simulation into minutes. AI/HPC compute servers can facilitate a revolutiojnary shift in simulation by utilizing the latest silicon processors and accelerators. Not only can CAD and CAE evolve through an efficient platform, but fine-tuning and optimization during the post-processing of automotive design can accelerate the overall time-to-market.

QCT boasts specialized teams of experts and AI/HPC servers powered by Intel® Xeon® Scalable processors that can be optimized to support CFD and FEA simulations and modeling, serving as a workload-driven infrastructure for automotive design. Automotive corporations can rely on QCT to assess the sizing and architecting of their CFD and FEA workloads, proposing the best-fit system architecture based on QCT servers. The latest Intel® Xeon® Max Processor is sutable for CAE, especially for memory-intensive HPC applications that can benefit from high-bandwidth memory (HBM) in Intel® Xeon® CPU Max with 64GB ultra-high-bandwidth in-package memory.

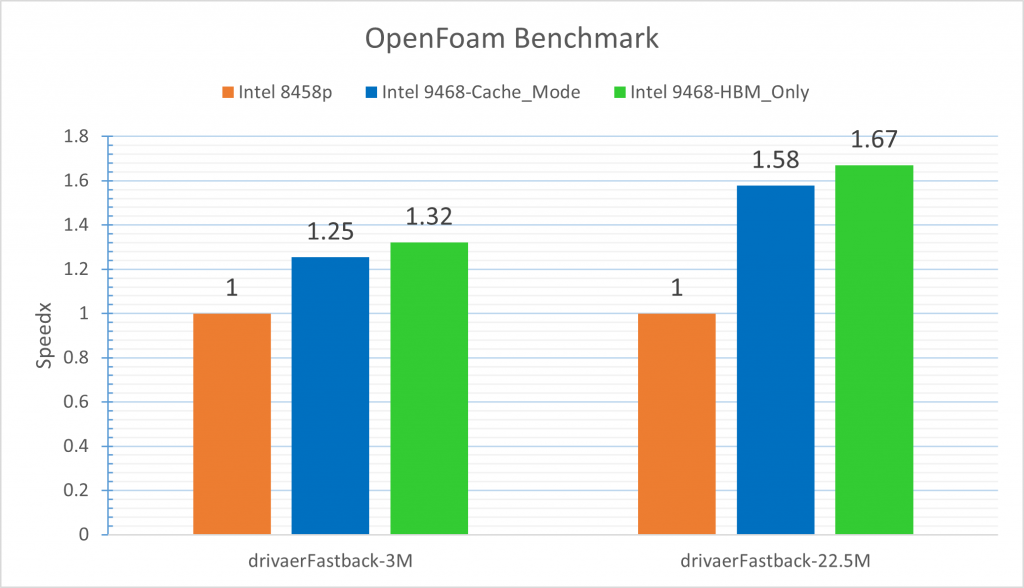

For example, OpenFOAM is among the most widely used CFD analysis applications in the automotive industry. QCT conducted several OpenFOAM benchmarks, comparing performance using both the 4th Generation Intel® Xeon® Platinum 8458P and the Intel® Xeon® Max 9468 processors. As shown in the figure below, the Intel® Xeon® Max 9468 Processor in HBM-cache mode and HBM-only mode demonstrated performance boosts of approximately 1.25 to 1.58X and 1.32 to 1.67X compared to the Intel Xeon Platinum 8458P processor, respectively.

While the HBM-only mode exhibits better performance compared to the HBM-cache mode, the limited capacity of HBM memory might pose challenges in real and practical scenarios due to insufficient memory usage. Thus, the HBM-cache mode appears to be regarded as the most practical solution, balancing performance and capacity for most applications.

QCT collaborates with Intel to offer the QCT DevCloud Program, providing users with a comprehensive HPC/AI/DA environment. This platform enables early technical performance evaluation, validation, and optimization by utilizing leading industrial CAE software for calculating fluid dynamics, structural analysis, vibration, and fatigue of components. This process leverages QCT servers integrated with Intel software and technologies, such as Intel® oneAPI, Intel® Advanced Matrix Extensions (Intel® AMX), OpenVINO™ Toolkit, and more. Key engineers in automotive companies can efficiently benefit from this program, comprehensively considering all possible outcomes before establishing a modern and new generation infrastructure designed for their CAE tools and applications.

Powered by 4th Gen Intel® Xeon® Scalable processors, QCT offers a full portfolio of servers that can be optimized for CAE tools:

- QuantaGrid D54X-1U – a general-purpose, rackmount, dual 4th Gen Intel® Xeon® Scalable processors server designed with a balanced architecture, built-in acceleration, and power efficiency. The D54X-1U offers twelve 2.5″ NVMe flash or sixteen E1.S NVMe flash drives, targeting HPC, AI, and enterprise workloads. Upgraded data protection with Intel® SGX, Intel® Crypto Acceleration, and PFR (optional)

- QuantaGrid D54Q-2U powered by 4th Gen Intel® Xeon® Scalable processors, the D54Q-2U is QCT’s leading PCIe Gen 5 platform. It supports up to 400GbE of networking bandwidth, up to two dual-width accelerators for AI inference workloads, and is offered in air-cooled and liquid-cooled variants.

- QuantaGrid D54U-3U an acceleration server designed for parallel computing. Supporting two 4th Gen Intel® Xeon® Scalable processors with up to 350W and 32x DIMM slots, this 3U system features support for four dual width accelerator cards or up to eight single width accelerator cards to provide a comprehensive and flexible architecture that can be optimized for various AI/HPC/DL applications.

Fig. 5 GPU node QuantaGrid D54U-3U

- QuantaGrid D74H-7U an acceleration server purpose-built to tackle the most complex HPC and AI workloads. Powered by the latest 4th Gen Intel® Xeon® Scalable processors family, it supports 32 DDR5 DIMM slots and is optimized to accelerate massive data sets, huge AI models, and supercomputing applications.

Fig. 6 GPU node QuantaGrid D74H-7U

As simulation becomes increasingly coupled to engineering and manufacturing, empowering automotive engineers with optimized solutions across their development process, from concept design to the final product, is of the utmost importance. Therefore, QCT offers a full ecosystem of data center technologies to bring innovations to life through digital transformation.

For more information on QCT QuantaGrid servers supporting CAE or AI/HPC workloads contact: [email protected]